DGS was born in 1994 from the experience of its founders in the field of plastic materials. At the beginning, in fact, our production was mainly concerned with two areas: on the one hand, the design and construction of moulds for plastic material and, on the other, the moulding of plastic material and zamak. In almost 30 years of history, the production activity of DGS has greatly expanded the range of its products, which are now a reference point on the national and international market.

However, one of our strong points, which has remained unchanged over the years, concerns our production, which has always been "Made in Italy". Since 1994, in fact, all our products are designed, manufactured and certified in Italy, in our production site in Bottanuco, in the province of Bergamo.

Growth in the markets

If at the beginning our production activity included only the production of moulds and the moulding of plastic materials, over the years it has evolved with the inclusion of new company divisions.

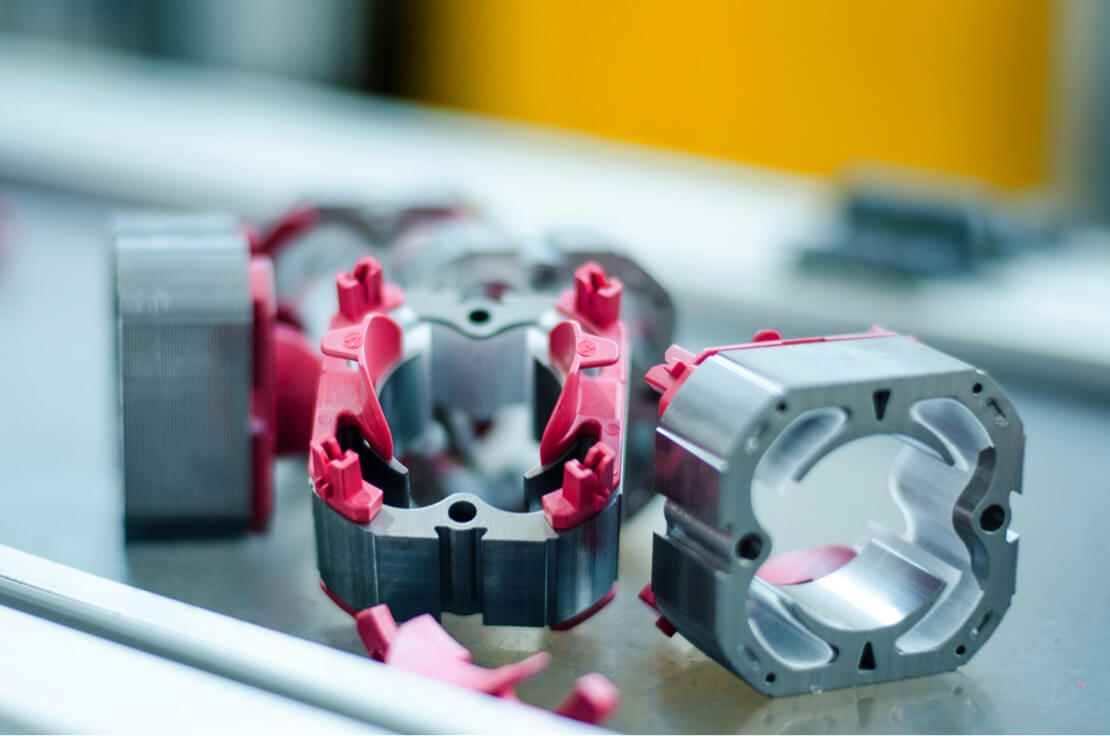

Thanks to the implementation of new production departments, we are now able to offer the market a wide range of processes: the winding of collector rotors, universal and brushless stators, the production of brushless rotors of various types, the production of turned and ground parts, the blanking of small metal parts and metal lamination rotor and stator, the design of electronic boards, all products in accordance with the quality standards of the market and certified ISO 9001:2015. Today, DGS has 7 business divisions:

Turning, grinding department and machining operations

Blanking of small metal parts

Rotor and stator laminations blanking

Rotor & stator winding and rotor assembly

Moulding department

Mold making and mechanical processing

Design and manufacturing of electronic boards

Centralized quality control office

What the 7 business divisions of DGS have in common is our internal quality control office, which is also equipped with a centralized metrology room that allows our highly qualified staff to perform all the necessary checks before the products are put on the market.

Specifically, our quality control staff verifies production start-ups, the conformity of molds and machining operations, as well as whether they fully comply with the customer's initial requirements.